Originally posted by Smoothound

View Post

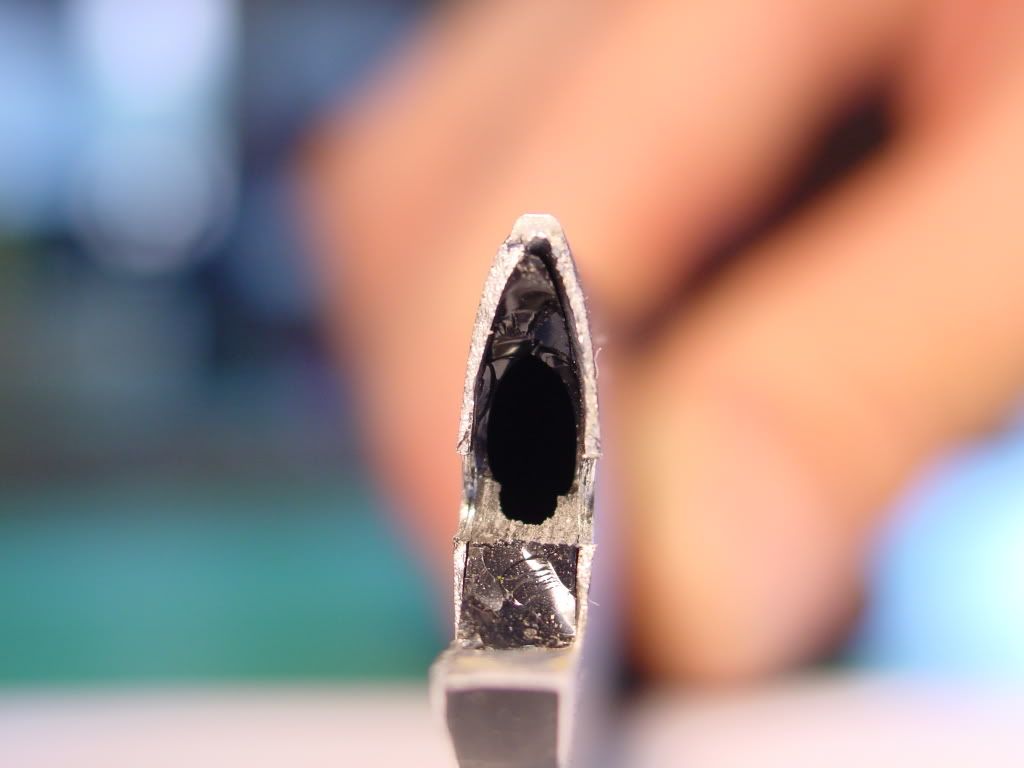

personnally when I see any signs of stress in the blades I will stop using them, as I mentioned before the chips all along the leading edge of the torsions, they never hit anything it was purely stress. Ive also had trouble with maniacs, weights comming loose, in that case the imported first of all accused me of abusing the blades, even though there are zero marks on the outside. ive been waiting over 2 months for the promised replacments from robbe even after numerous calls and proken promises. so im needing to find another blade type I like, therefore finding this thread extremely interesting

Comment